Medical Device Prototype Hub

Service Offerings

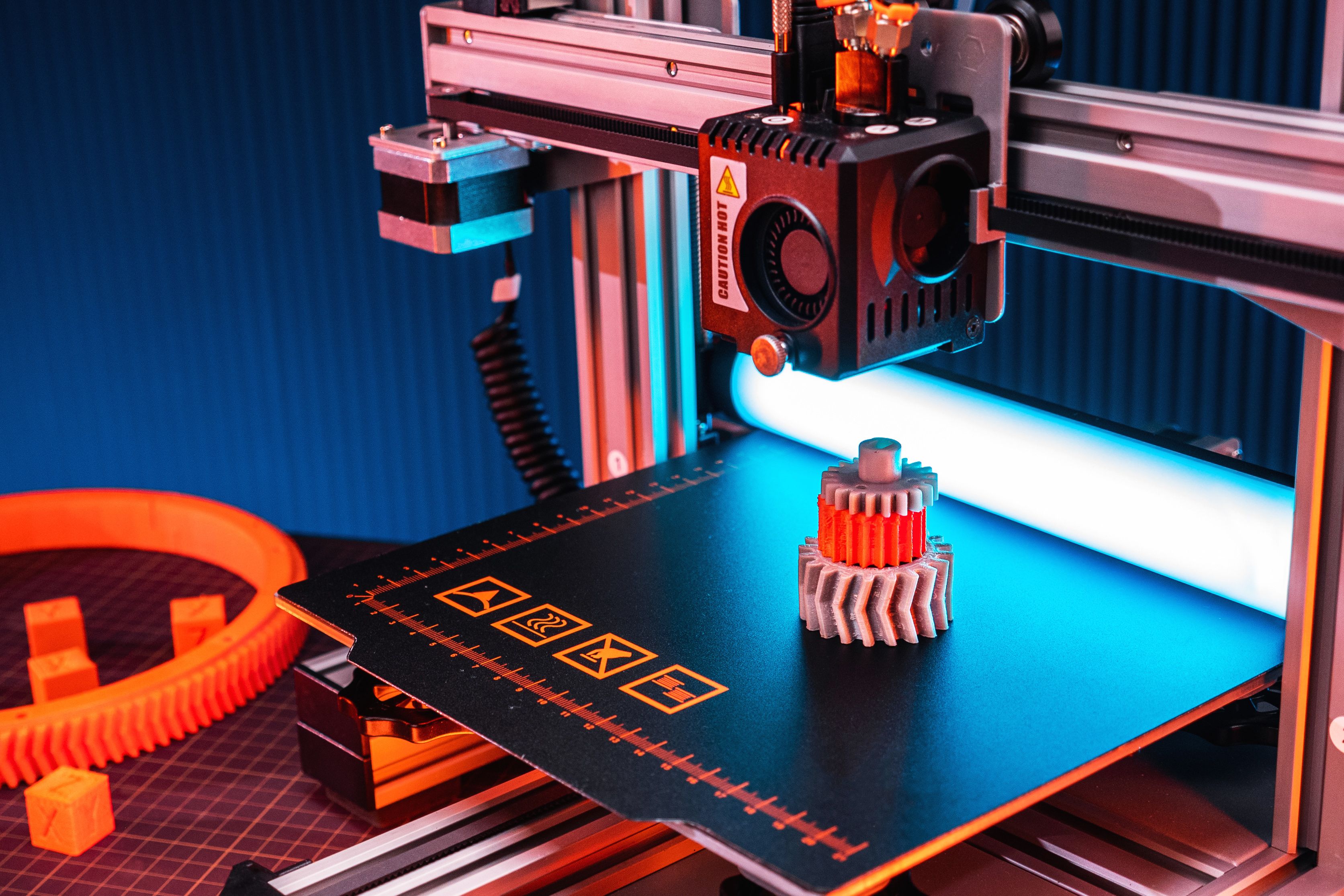

The Medical Device Prototype Hub, supported by Medtronic, at the University of Galway offers a comprehensive suite of services to support early-stage medical device innovation. The Hub provides both virtual and physical prototyping, enabling rapid design iteration through CAD modelling and simulation.

As a core facility we provide a full service one stop solution for 3D printing needs, which includes a host of expert led design, printing, and consultancy.

It is equipped with state-of-the-art additive manufacturing technologies, including SLA resin, multi-material FDM printing. The facility also supports micro and nano-computed tomography (CT) imaging and pre-clinical testing for validation of prototypes. The PT Hub currently operates five 3D printing machines as a core service to researchers, collaborators and industry partners.

Our Service Portfolio Includes:

- Technical Consulting: for grant applications and spin-out projects: early-stage brainstorming and prototyping (physical and virtual), budgeting for design and prototyping support, IP and FTO support, support towards completing technical work packages through engagement with internal (UoG) and external technical experts, review of technical and non-technical pitch decks, COGS analysis.

- Technical consulting for Industry: CT imaging, Industry-University collaborations

- Model generation and CAD designing of parts and assemblies

- 3D Print Manufacturing using SLA/FDM technologies

- Postprocessing and assembly, assistance with benchtop testing

- Knowledge transfer and training

Our Equipment Portfolio Includes:

|

Formlabs 3BL |

The Formlabs 3BL is a large-format SLA 3D printer designed specifically for medical applications, capable of producing full-size anatomical models and large medical device prototypes with high precision and repeatability. It uses Low Force Stereolithography (LFS) technology, which allows for detailed prints with minimal stress on parts, supporting a wide variety of biocompatible, sterilizable materials validated in FDA-cleared workflows. Key specifications include a build volume of 33.5 × 20 × 30 cm, XY resolution of 25 microns, layer thickness from 25–300 microns, dual 250 mW lasers, and automated resin handling. Applications: Full-scale anatomical models, medical device prototyping, jigs, fixtures, and end-use parts. Resins Available: Clear v4, Grey v4, Biocompatible Durable Resin v1

|

|

Sonic Mini 8K |

The Phrozen Sonic Mini 8K is a high-resolution resin 3D printer featuring an 8K monochrome 7.1” LCD screen with an XY resolution of just 22 microns, enabling extremely detailed and precise prints. It offers a build volume of 16.5 × 7.2 × 18 cm and supports layer thicknesses from 0.01 to 0.30 mm, with a maximum printing speed of around 80 mm/hour. Its linear projection LED module enhances light uniformity for sharp, consistent curing, paired with ultra-stable dual linear rails that ensure printing stability. Compact and lightweight, it is suitable for highly detailed miniature prototyping applications. In a medical device prototyping hub, the Sonic Mini 8K excels at producing fine anatomical models, and intricate parts where surface detail and accuracy are crucial, supporting iterative design and validation in a compact footprint. Resins Available: AquaGrey 8K

|

|

Bambu A1 |

The Bambu Lab A1 is a fully automated, CoreXY FDM 3D printer featuring a build volume of 256 × 256 × 256 mm, ideal for both beginners and enthusiasts looking for high-speed, precision printing. It boasts an all-metal hot end with a maximum temperature of 300°C, quick-swap nozzles, and a heated build plate that reaches up to 100°C, supporting common filaments like PLA, and PETG. The A1 integrates advanced auto-calibration systems for bed leveling, Z-offset, and vibration resonance, combined with filament sensors for run-out, tangles, and odometry to enhance print reliability. Its user-friendly ecosystem, including Wi-Fi connectivity and Bambu Studio software, facilitates multi-color printing with the AMS Lite upgrade, making it versatile for prototyping. In a medical device prototyping hub, the A1’s balance of speed, accuracy, and automation supports rapid iteration of small to medium-sized device components, enclosures, and functional prototypes with reliable material options and streamlined workflow. Filament Compatibility: PLA, PETG

|

|

Bambu X1C |

The Bambu Lab X1C (X1 Carbon) is a CoreXY FDM 3D printer optimized for speed, reliability, and the versatile use of advanced engineering materials. Its key specs include a build volume of 256 × 256 × 256 mm, maximum print speed of 500 mm/s, 20 m/s² acceleration, dual auto bed leveling, 300°C all-metal hot end, and a hardened steel nozzle for printing abrasive filaments like carbon and glass fiber-reinforced polymers. Advanced features such as 7 μm Lidar resolution, AI-powered first layer inspection, spaghetti failure detection, and multi-color/multi-material printing with Automatic Material System (AMS) set it apart for professional use. The X1C’s enclosed build, automatic calibration, humidity-controlled filament compartments, and HEPA air filtration makes it suitable for medical device prototyping where reliable dimensional accuracy, clean environment, and material options are critical. In a medical device prototype hub, it enables rapid creation of functional device enclosures, mechanical test parts, or moulds. Filaments Available: PLA, PETG, TPU, PVA, carbon fiber-reinforced PLA and PETG.

|

|

Bambu H2D |

The Bambu H2D is a high-performance all-in-one 3D printer offering a large build volume of up to 350 × 320 × 325 mm and supporting advanced multi-material Fused Deposition Modeling (FDM). It features dual 350°C nozzles, active heating up to 65°C, print speeds up to 1000 mm/s, and supports engineering-grade filaments such as carbon and glass fiber-reinforced polymers. Key specifications also include a robust CoreXY motion system, flexible PEI build surfaces, automated bed leveling, multiple cameras (including live view and nozzle cameras), and enterprise-grade security features for professional environments. Beyond 3D printing, the H2D supports laser engraving/cutting, digital cutting for vinyl, and pen plotting, enabling rapid prototyping with plastics, wood, paper, leather, and composites. For a medical device prototyping hub, the H2D’s versatility allows for quick creation of parts, fixtures, moulds and enclosures from clinically relevant materials, with its heated chamber and high-temp dual extrusion enabling functional and durable medical device prototypes for iterative design and testing. Filaments Available: PLA, PETG, TPU, ABS, PVA, carbon fiber-reinforced PLA and PETG.

|

Our team will be happy to assist you in select a material and/or a technology to use for your 3D Printing application. We can evaluate your design for “printability” and provide a price quote in advance.

Please note that the Hub will only be offering the resins and filaments mentioned above.

If any project has a specific material requirement which is not offered at the PT-Hub currently, e.g., specific engineering resins, resin tanks, high temperature filaments, etc., they will need to be procured by the research projects themselves as part of their engagement with the Hub.

The hub will conduct timely assessment of material needs across all the research projects it engages with on an ongoing basis and change the resin and filament offerings based on the demand from projects and the financial viability of procuring them.

Access Charges for Printers:

|

Printers |

Academic Rates per Hour for Autonomous use* |

|

Formlabs 3BL (Resin SLA) |

€17 |

|

Sonic Mini 8K (Resin SLA) |

€10 |

|

Bambu A1 (FDM) |

€6 |

|

Bambu X1C (FDM) |

€10 |

|

Bambu H2D (FDM) with laser cutting and engraving |

€11 |

*Rates for Assisted use are also available. Please reach out for further details.

Design and Consulting rates are available upon request upon project outline.

Industry rates are available upon request and project consultation.

Contact

Email: pthub@universityofgalway.ie

This facility is part of the Technology Services Directorate (TSD).